Elevating Manufacturing in Utah

Elevate - Salt Lake City Opening

Elevate - Salt Lake City Opening

Our Ambition

As Elevate Commercial Roofing Systems continued to expand its commercial presence across North America, it became clear that a larger and more efficient manufacturing and distribution center was necessary to support the growing demands of the Western U.S. and Canadian markets.

The previous 300,000-square-foot facility was no longer sufficient, and Elevate needed a space that could enhance delivery times, improve product availability, and increase production capacity — all while maintaining a strong commitment to sustainability and innovative roofing systems.

The new facility boosts production capacity of Elevate ISOGARD polyiso insulation, adds new production line for Elevate UNA-CLAD metal products, and serves as a regional distribution center for all Elevate product lines.

It is also the largest industrial / manufacturing project in Utah to be certified under LEED v4, and a first in Salt Lake City. This meant incorporating energy-efficient solutions and innovative material choices into the building’s design. A key challenge was selecting a roofing system that could withstand Salt Lake City’s diverse climate, which includes extreme heat, heavy snowfall and strong winds. Additionally, the roof needed to be designed with future sustainability in mind, including the potential for solar panel installation.

The Solution

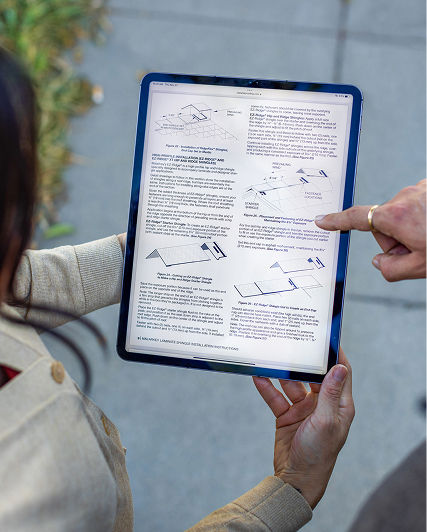

To address these challenges, Elevate selected a high-performance commercial roofing system that combined durability, energy efficiency, and long-term sustainability. Utah-based Redd Roofing, who is a respected Elevate licensed contractor, installed the system. They’re also a recipient of the 2025 Master Contractor Presidents Club award and are a member of the prestigious Hall of Fame.

The roofing solution featured Elevate UltraPly™ TPO, chosen for its high solar reflectivity, UV resistance, and durability. By reflecting sunlight rather than absorbing heat, this membrane helps lower cooling costs, creating a more energy-efficient facility. To further enhance thermal performance, ISOGARD™ Polyiso Insulation was installed, delivering up to 40% better cold-temperature performance compared to other roofing insulation brands.* This improvement in insulation contributes to significant energy savings by reducing heating and cooling demands throughout the year.

To reinforce durability, Elevate Edge Metal was integrated into the roofing system, adding enhanced perimeter protection and providing critical performance against high winds and moisture while enhancing the overall stability of the roof. Beyond its functional benefits, the edge metal also contributed to the building’s clean, polished aesthetic.

In addition to these core roofing components, other advanced materials were incorporated to optimize performance and environmental impact. UNA-CLAD™ Metal wall panels provided exterior durability and a modern appearance, while SunWave™ Skylights maximized natural daylight, reducing the facility’s reliance on artificial lighting and lowering overall energy consumption. The roof was also designed to support future solar panel installation, ensuring that Amrize's commitment to clean energy would extend beyond the initial construction phase.

Elevate - Salt Lake City Opening

Elevate - Salt Lake City Opening

The Results

Elevate’s new 650,000-square-foot Elevate Manufacturing & Distribution Center in Salt Lake City more than doubled the company’s previous facility, improving production capacity and service to the Western U.S. and Canadian markets. It became the first in Salt Lake City to achieve LEED v4 Certification, meeting the highest standards for sustainable building design and efficiency.

The facility’s energy-efficient roofing system played a key role in achieving this certification. UltraPly™ TPO reduced cooling costs through high solar reflectivity, while ISOGARD™ Polyiso Insulation improved thermal performance. Additional features, such as SunWave™ skylights and UNA-CLAD™ metal wall panels, further enhanced sustainability, longevity and durability.

Reinforcing our commitment from foundation to roof, additional product brands from the Amrize portfolio featured prominently in the build. FortiCem®, part of our ECOPlanet low-carbon cement portfolio, contributed to LEED v4 certification, significantly reducing the CO2 footprint of the building’s footings, foundation, floors and tilt panels. Additionally, walkways and loading docks use anti-slip coatings from American Safety Technologies® and PolySpec® THIOKOL® primer.

The project earned industry recognition, including the 2024 Architectural Products Product Innovation Award (PIA) for its innovative and environmentally responsible design. The new Elevate facility sets a benchmark for sustainable manufacturing and distribution in the commercial roofing industry.

*The thermal performance of ISOGARD polyiso insulation is up to 40% better than major competitors when tested by an independent third party in cold-temperature 40°F (4°C) applications according to ASTM C1289 standards. The increased R-value per inch means better thermal performance from the same roofing systems using the same amount of insulation compared to leading competitive products on the market today.

**Information is valid at the time of publication and may change.