Working Overnights: How YVR Got a New Runway While Keeping Flights on Time

YVR’s North Runway is a critical link in its operations, handling nearly 400 daily flights.

YVR’s North Runway is a critical link in its operations, handling nearly 400 daily flights.

Just after nightfall, once the final aircraft had departed, Vancouver International Airport’s (YVR) North Runway shifted into a different kind of operation. Lights came on, equipment was stationed, and construction teams moved into position. For the next eight hours, Amrize teams would work across one of Canada’s busiest runways—with the understanding that by sunrise, they’d have it ready for commercial traffic once again.

Initially constructed in the 1990s, the North Runway was in need of an upgrade. As a critical part of YVR’s airfield network that handles hundreds of aircraft movements each day, the work was carefully planned to take place during six months of overnight shifts starting at 10 p.m. By sunrise every day, crews returned the runway to service with its surface, line painting and lights ready to safely accommodate the day’s flights schedule. This overnight window would shape every aspect of the project.

Planning for success: The daily routine that kept nightly paving on schedule

For six months, crews worked overnight to upgrade three kilometers of active runway, conducting paving within the 8-hour closure period.

For six months, crews worked overnight to upgrade three kilometers of active runway, conducting paving within the 8-hour closure period.

Each evening before the shift began, teams reviewed minute-by-minute schedules, examined weather conditions, and coordinated assets for the night shift. Since all work had to be completed, inspected, cleaned up and handed back to airport operations before the first morning arrival, planning and communication were just as crucial as the paving itself.

“Amrize deployed dedicated, highly trained crews to deliver a complex paving program under a tight scheduling window. The Mitchell Island team ensured the 400-tonne-per-hour plant maximized uptime and produced consistent, high-quality asphalt mix. Pave teams mastered the use of dual 10-meter screeds paving in echelon with mm GPS control—an approach that minimized cold joints, improved ride quality, and elevated productivity.”

The right mix: Specialized asphalt and paving techniques make for fast work

Runways must withstand heavy planes and near-constant traffic. Working in partnership with Kiewit, YVR’s General Contractor, Amrize supplied and placed approximately 154,000 metric tonnes of advanced asphalt solutions across the entire North Runway and its connecting taxiways

The asphalt mix incorporated additives and fibers to make it stronger and longer-lasting. It was also produced with Environmental Product Declarations (EPDs), which provide transparent information about the environmental impact of the materials.

Well-oiled machines: Technology delivers consistency night after night

Even in the middle of the night, the team setup demonstrated how careful planning and skilled execution could keep projects of this complexity moving smoothly.

Even in the middle of the night, the team setup demonstrated how careful planning and skilled execution could keep projects of this complexity moving smoothly.

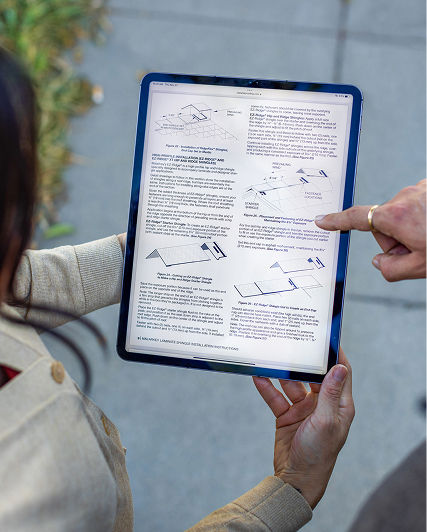

With 100 crew members operating 100 pieces of equipment across the full project night after night, consistency was critical. For Amrize’s portion, that meant managing up to 60 milling and paving units, supported by 30 trucks and transfers to keep material moving efficiently. Technology lent a hand. To ensure repeatable results over the program, while maximizing efficiency, quality and speed. Amrize used advanced systems, including:

- mmGPS Paver Control: Automated screed adjustments for consistent surfaces

- Thermal Imaging: Real-time monitoring of asphalt temperature for optimal compaction

- Wide Screeds: Fewer joints, greater efficiency, higher nightly volumes

Together, these tools helped Amrize lay 220 millimeter-depth overlays in 120-meter increments—ultimately providing a smooth, uniform surface across the 65-meter-wide, three-kilometer-long runway and its 11 taxiways.

Team dynamics: Partnership delivers on-schedule results

The whole program spanned 221,000 square meters per lift of pavement, making it one of the most extensive airfield resurfacing projects undertaken in Western Canada in recent years.

The whole program spanned 221,000 square meters per lift of pavement, making it one of the most extensive airfield resurfacing projects undertaken in Western Canada in recent years.

The North Runway Program shows the power of a close partnership between YVR, Kiewit, Amrize, and the broader construction and operations teams. Through extensive pre-planning, high-performance materials, and specialized equipment, the project stayed on schedule throughout the six months of construction, which concluded in Fall 2025.

YVR’s North Runway has returned to full service, with paving and major improvements completed on time.

YVR’s North Runway has returned to full service, with paving and major improvements completed on time.

The approach—nightly work, innovative materials, precise execution and seamless handovers—is now drawing interest from airports across North America looking to modernize major airfield infrastructure while keeping flights on schedule, passengers on the go and airlines doing business.