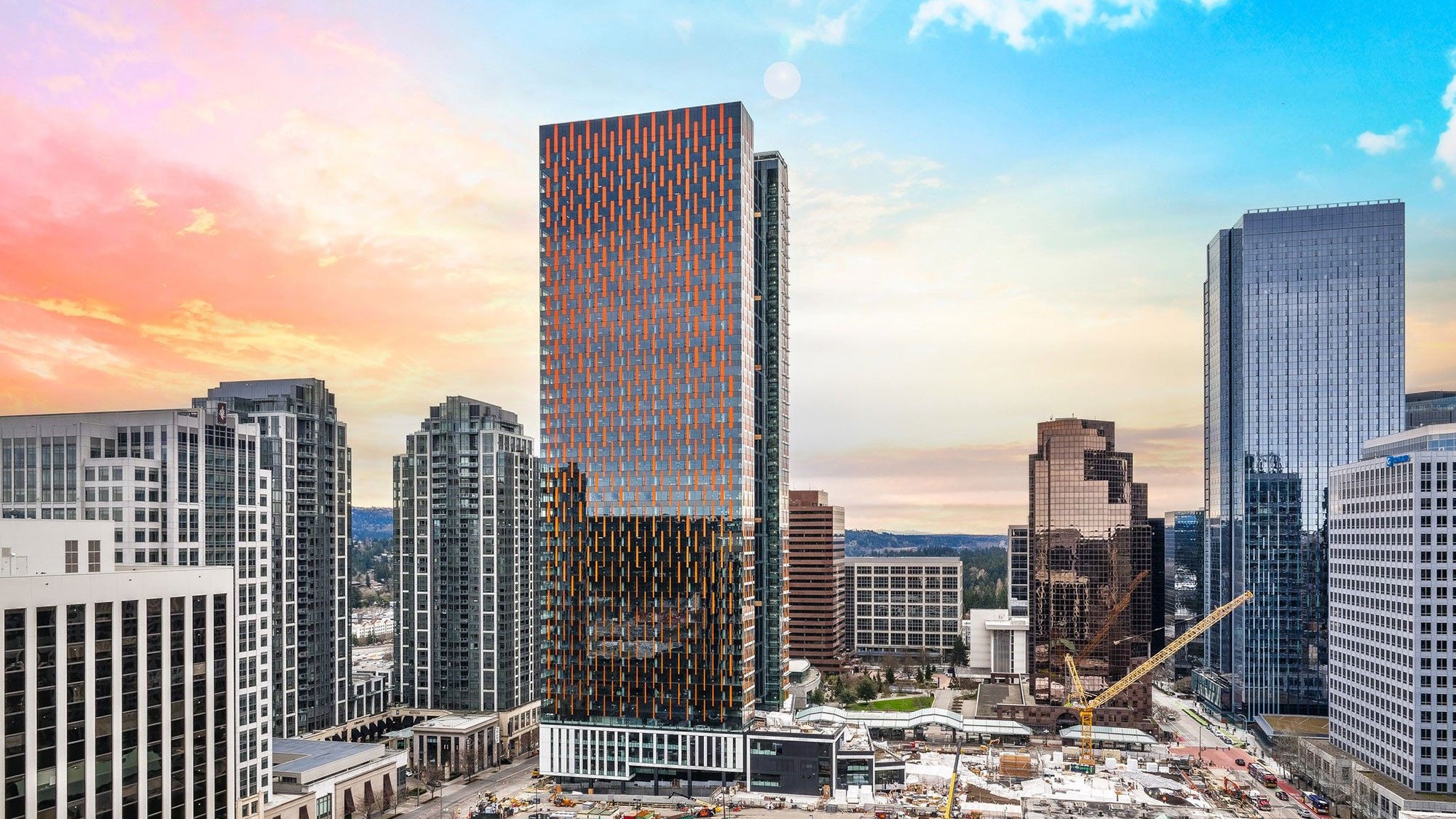

Delivering with Amazon: The big innovation with a small footprint inside Bellevue 600

Amazon challenged its design, construction and material supply teams to pilot new materials for its Bellevue 600 development in downtown Bellevue, Washington.

Amazon challenged its design, construction and material supply teams to pilot new materials for its Bellevue 600 development in downtown Bellevue, Washington.

It started with a challenge from Amazon: Pilot new materials to help us decarbonize our buildings and push construction forward.

It ended with Bellevue 600, Amazon’s new office tower in Washington state, featuring a first-of-its-kind, near-zero-Portland cement concrete with a 62% lower embodied carbon footprint.

In between is a story of cement and concrete industry leaders who rose to meet Amazon’s needs.

In their own words, read how Don Davies, co-founder of Davies-Crooks Associates, and Rob Shogren, senior director of quality and product performance for Amrize, joined Amazon in reimagining what’s possible in lower-carbon concrete.

Meet the lower-carbon concrete project leaders:

Don Davies

Don Davies is the co-founder of Davies Crooks Associates and head of the ClimateWorks Lower Carbon Concrete Task Force. A 35-year structural engineer, Don is the former president of MKA, the structural engineering firm behind Bellevue 600.

Rob Shogren

Rob Shogren is the senior director of quality and product performance for Amrize, overseeing product development and performance for all Amrize cement plants, grinding facilities and other cementitious manufacturing facilities.

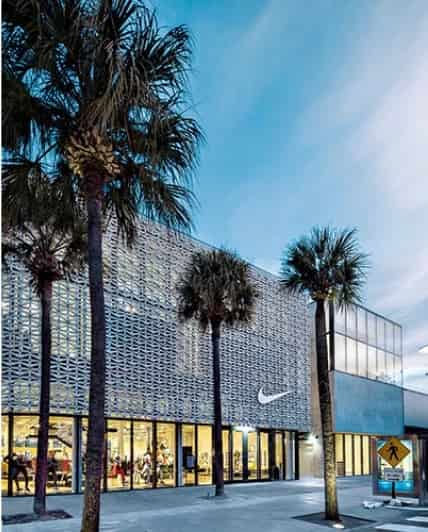

The Amazon Bellevue 600 Office tower rises 43 stories and significantly expands Amazon’s presence in Bellevue, Washington.

The Amazon Bellevue 600 Office tower rises 43 stories and significantly expands Amazon’s presence in Bellevue, Washington.

Take us back to the beginning. How did Amazon start this conversation with you?

Don Davies: Amazon asked for lower-carbon concrete solutions. They wanted new ideas. They didn’t tell anyone how to do it. They said: We have an aspiration to decarbonize and move the industry forward from where we are today. We’re willing to back it up with our name and try something out on our own projects. Tell us what’s possible.

I had been working with Amazon through the ClimateWorks Lower Carbon Concrete Task Force when they brought Bellevue 600 up as the next opportunity. I knew the project well from my prior work. It already had multiple lower-carbon strategies, but construction was still in the early stages with much concrete to be poured.

MKA, where I’d previously been president, was the original structural engineer for the development, and Amazon wanted to retain the approved design and performance goals. The challenge was to collaborate with the original design and construction teams, maintaining their design while showcasing how to responsibly offer new ideas and innovation at the concrete procurement, delivery and placement points.

With this table setting, I thought, “Who are some of the smartest people I know in this space?” So, I called Amrize and Rob.

The Seattle Spheres is a LEED Gold-certified building, built with Amrize’s advanced cement to deliver a more than 80% CO2 reduction over the industry average.

The Seattle Spheres is a LEED Gold-certified building, built with Amrize’s advanced cement to deliver a more than 80% CO2 reduction over the industry average.

Rob Shogren: Don and I met at the time of the Seattle Spheres project—I helped put together its mix designs. He brought me in for a tour of Bellevue 600 when it was just coming out of the ground and presented the Amazon challenge. That’s when the idea of piloting super-sulphated cement slag came up.

With the construction of the Bellevue site, Amazon aims to contribute to a thriving downtown, where people live, work and visit—not just drive through.

With the construction of the Bellevue site, Amazon aims to contribute to a thriving downtown, where people live, work and visit—not just drive through.

How did you go from an idea about a novel material to using it in Amazon’s HQ?

Rob: Our Seattle cement plant had the equipment to scale up this new binder and was looking for ways to differentiate itself in the market. The team is very nimble, so we went from benchtop trials in November to an actual grind in December and January. Then we trialed it with our close ready-mix partner, Stoneway Concrete, who happened to be the supplier for Bellevue 600.

It was pretty nerve-wracking to put it into a building like this and make sure it did what it was supposed to. Even after all the testing, I was on pins and needles for the first week to make sure that the team got the initial results we wanted.

Don: Rob and his team didn’t just invent a new mixture and then start pouring it on a high-rise building the next day. This started with lab trials, then in-field mock-ups, then non-structural applications.

Going from developing a novel material to testing through mock-ups and field placements to project-ready acceptability requires multiple steps. We responsibly and systematically brought this forward, including keeping the city and design teams fully informed about the results along the way.

Since this was a pilot, how did you determine where you could use this mix?

Don: We looked at slab and column applications in the mockup, doing the field trials twice to get them right. The next question I remember Rob challenging us with was, “Come on, guys, it’s not enough just to do this in a pilot trial if we’re getting good results. Where else can you use it on the project?”

So, the team started looking around. How much more can we use? Where else can we use it? After talking with the ownership, design and construction teams, opportunities just started presenting themselves. “Well, let’s do these housekeeping pads here. Well, what about this other piece of concrete over here?”

Amrize developed the material in collaboration with concrete supplier, Stoneway, General Contractor, Sellen Construction, and the development and design teams of Seneca Group, NBBJ and MKA.

Amrize developed the material in collaboration with concrete supplier, Stoneway, General Contractor, Sellen Construction, and the development and design teams of Seneca Group, NBBJ and MKA.

Experimentation always comes with ‘learning opportunities.’ What were some of yours?

Rob: There are things you learn and put on a checklist for next time. Because this mixture doesn’t have much clinker in it, there is lower self-generated heat. That’s great for hot-weather concrete, but it will set more slowly in the cold. On one of our last placements, it was 36°F outside. It took longer than we wanted for the stuff to set on that pour, so that was a Eureka moment. It gave us knowledge for future placements.

Don: There are places where using the mixture is better, and there are places where Rob would be the first to say, “Let’s do something different.” With Rob, it’s like looking under the car hood with an ace mechanic and a big toolkit. He has more than one wrench in his toolbox, and he knows just the right tool to use in each application.

Rob: I’ve found we need to do a very good job of educating people on how these mixes perform differently. Some of these lower-carbon mixes are very, very good at long-term durability, but you have to know how to place them, how to finish them.

The concrete exceeded strength and placement expectations, offered positive shrinkage control and no unexpected cracking, and provided smooth, uniform finishes.

The concrete exceeded strength and placement expectations, offered positive shrinkage control and no unexpected cracking, and provided smooth, uniform finishes.

What role did Amazon play in making this project a success?

Rob: Amazon’s trust was critical. When Amazon comes to us and says: If you say it’s going to work and you can back it up, we’re going to go with it, that makes things move a lot faster. A huge portion of this is having customers who are willing to explore new things.

Don: While we can test and de-risk the mechanical properties of the materials, Amazon’s backing was huge for de-risking the efforts needed for Amrize, Stoneway and Sellen construction to bring these materials forward. So, I want to give a shout-out to Amazon and their owner’s representative, Seneca Group, for their leadership. They created the team culture and environment to move this forward.

The completed tower, reflecting Amazon’s vision for an environmentally focused, human-centered workplace.

The completed tower, reflecting Amazon’s vision for an environmentally focused, human-centered workplace.

What about Amrize’s part? What did we ‘add to the mix?'

Don: When we’re talking about lower-carbon concrete, it’s not just a material science challenge; it’s a scale problem. How do we bring solutions to scale? This is what gets me excited about Amrize in this conversation. Amrize has the facilities, the distribution networks, and the skill to deliver at scale.

Rob: If you’re not able to scale, it’s just going to be a science project—it’s not going anywhere fast.

Don: Amazon saw how this could work. They saw the potential for duplication on more than one project. When talking about scale, Amazon can say: We want to go and use it in this data center or that distribution center at higher volumes. That’s how the system is supposed to work.

What’s so exciting about working with people like Rob and Amrize: It’s experts doing what they do well, and then a support system scaling and repeating it.

The tower’s design creates a space where people can work, connect and thrive.

The tower’s design creates a space where people can work, connect and thrive.

You achieved a mix with a 60% lower embodied carbon footprint that exceeded strength and placement expectations. What does this mean for the future?

Don: When I think about Bellevue 600… It’s a beautiful building, but it’s also a traditional application and use case for concrete. What’s exciting is changing the fundamental core materials we’re using—making much lower-carbon concrete—while still delivering the same basic product performance and building. To me, that’s innovation.

There’s more concrete material science innovation today than I’ve seen in my 35-year career, because we’re challenging the fundamentals. What is the material? Can we find value-add solutions that are different, better? Oh, by the way, also have a lower-carbon footprint? When we have solutions working in this order, great things can happen.

I think Bellevue 600 is a great case study of what’s possible and how to responsibly bring new concrete materials and ideas forward. It’s the industry rising to a challenge and bringing real innovation to the table in ways we haven’t seen in the past.