Concrete, now with AI. See how at the new Meta data center

Data centers are the fastest-growing construction segment in the United States.

Data centers are the fastest-growing construction segment in the United States.

Meta has announced it will more than double its investment in AI infrastructure, including data centers. That’s a whole lot of gigawatts, superhuman thinking—and construction. One of the ironies of the digital economy is that it requires a vast amount of physical building. And for Meta, with its goal of being net zero by 2030, that brings the opportunity to build more efficiently.

Enter AI-optimized concrete. It allows hyperscalers to achieve the perfect concrete mix for their sustainability, speed, strength or other needs faster and better than manual mixing.

Here’s how Amrize, the University of Illinois Urbana-Champaign, and Meta collaborated to create a first-of-its kind AI-optimized mix for surface use that was 43% faster in early strength and 35% less carbon intensive—all at similar cost.

Concrete houses critical equipment in an AI data center. Photo courtesy of Meta.

Concrete houses critical equipment in an AI data center. Photo courtesy of Meta.

What is the role of concrete in AI data centers?

Data centers are important, explains Meta Principal Research Scientist Julius Kusuma, because they’re where Meta houses the technology that helps people use artificial intelligence (AI) to improve their lives. And concrete is important for a data center facility, he adds, because that’s where critical equipment resides. “The computing resources, the AI, the networking equipment, the cooling systems, the data storage, and everything else.”

Mixing concrete for these types of slab or surface applications is more difficult than doing so for foundations or formed shapes, says Julius. “It requires a good finish quality for the installation, operation and maintenance of mission-critical servers, cooling and power equipment.”

Empowering the digital economy from the ground up

Amrize doesn’t stop at advanced concrete mixes. We uniquely empower the digital economy from foundation to rooftop. Our building envelope solutions, including roofing and wall systems, sealants and insulation, are crucial to maintaining secure, consistent environments in data center hubs, distribution centers and warehouses. Our solutions also help build the supporting roads, utility systems, and more needed to help these facilities thrive.

Why use AI to optimize concrete in Meta data centers?

Mixing concrete is rather like baking a cake. It has a mix design—aka a recipe—with different proportions of ingredients, in this case things like aggregates, water and cement.

The ‘recipe’ has a wide range of variables to achieve different results, explains Mark Bintzler, a general manager and tech services manager who’s been with Amrize for 31 years.

“We can make it stronger; we can make it set faster; we can make it shrink less or shrink more. It’s a tremendous amount of data, and what AI is good at is processing a lot of data. We can do it manually. But it’s much faster with AI.”

Construction pros install concrete at Meta’s AI data center in Rosemount, MN. Photo courtesy of Meta.

Construction pros install concrete at Meta’s AI data center in Rosemount, MN. Photo courtesy of Meta.

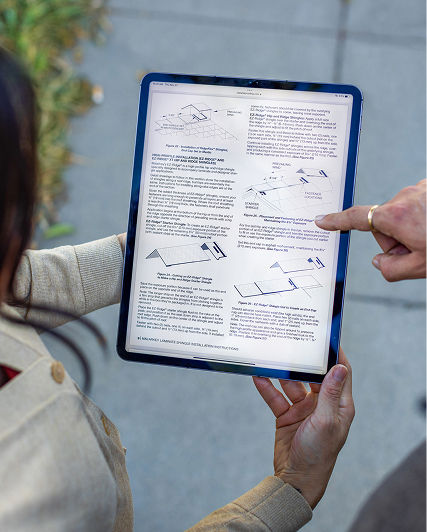

How do you use artificial intelligence models to mix concrete?

Meta launched a collaboration with the University of Illinois to generate, mix and test recipes in the lab—creating data that trains the AI model Meta developed. When the tech leader brought in Amrize as the main concrete supplier for its new data center in Rosemount, MN, the project moved from theory to practice.

Amrize provided the concrete ingredients for university scientists to test, ensuring a match between the lab and the site. It also provided real-world expertise.

“Learning the field-specific challenges and opportunities from Amrize was very important,” shared University of Illinois Urbana-Champaign assistant professor Nishant Garg, “because they’re the ones who are making the concrete that is poured into the slabs.”

Amrize poured 570 yards of AI-optimized concrete at Meta’s Rosemount, MN, data center.

Amrize poured 570 yards of AI-optimized concrete at Meta’s Rosemount, MN, data center.

“An AI model may be able to put out information and predictions, but those may not be achievable in the field,” agrees Darryl Neopolitano, who has extensive hyperscale data center experience as manager of major construction projects for Amrize. “Our team can say, ‘you should only target this specific portion of the aggregates range,’ for example. It becomes more practical than theoretical.”

As Professor Garg puts it, AI is a tool. “It’s useful and powerful, but you still need a human being involved.”

The Amrize, Meta, and University of Illinois team met every two weeks to discuss their results and refine the AI-optimized mixes.

The Amrize, Meta, and University of Illinois team met every two weeks to discuss their results and refine the AI-optimized mixes.

What was the outcome for the Rosemount, MN, Meta data center—and beyond?

For Meta, the main impetus for using AI was to reduce the embodied carbon of its data centers. And it did that, achieving a formula that was greener, faster, stronger, and cost-neutral, while using regular materials, notes Julius.

But low-carbon concrete for one Meta data center in Minnesota isn’t the end of it. The artificial intelligence model is open-sourced, and Meta invites others to download the code from Github.

“With open source AI models, everybody leap-frogs to that level,” says Professor Garg. “If we want to improve concrete, it won’t help the overall industry if only one company has better concrete and the remaining concrete producers lag behind. My aspiration would be 10 years from now, we have this happening at scale at all the ready-mix concrete plants in the world.”

Speed and strength of concrete mixes are still important to hyperscalers, but environmental impacts are growing in importance too.

Speed and strength of concrete mixes are still important to hyperscalers, but environmental impacts are growing in importance too.

What does this mean for the concrete industry and concrete production?

Randy McCullum, a commercial operations manager and 25-year Amrize veteran, agrees that organizations aren’t going to ignore opportunities to be more efficient. “We are still working toward this being the norm,” he observes, “But the Googles, Metas and other tech companies are doing it—and we can be leaders in our industry.”

And that’s not the only benefit he sees from advanced manufacturing. “One of the things I hear a lot from customers is the need to attract new talent. If we’re looking to the future, if we want to keep this industry an attractive industry, innovation is critical.”

Mark reflects on how the construction industry has continuously evolved, with surveying a prime example. “When you’re in college in the 80s you’re pulling metal chains to measure stuff. And now it’s GPS. They stick a stake in the ground and satellites tell you where they are.”

A hyperscaler facility. Amrize provides both the building materials and the building envelope, here roofing.

A hyperscaler facility. Amrize provides both the building materials and the building envelope, here roofing.

Is AI-optimized concrete the future of our built environment?

Concrete is often seen as immutable—so much so that it’s a synonym for solid and fixed. But AI is only one of the ways it’s moving forward. Novel resources, like calcined clays and harvested ashes—known as supplementary cementitious materials (SCMs)—are another.

Often, these advanced approaches work together. For example, Professor Garg’s lab has developed a test that cuts performance predictions for SCMs from seven or more days to five minutes. If effective, these SCMs can provide useful inputs for the next generation of AI models to predict long-term strength in less than the time it takes to make a cup of coffee.

There’s a long way for AI to take us. As Darryl puts it, “We’re probably in elementary school in the scope of digital transformation. “We’re not even into middle and high school—let alone college and grad school.”

Graduating with honors will be a team effort, concludes Julius—in this case, across the construction industry and beyond data center design. “There’s a lot of opportunity for different parties to collaborate: the general contractors, the concrete and material suppliers, the building owners… Because we all have a stake in revolutionizing the most used material on our planet. If we work together, I think we can advance how our world builds the future.”